|

|

Mouldy

Joined: 10 Aug 2011

Posts: 107

Location: Birmingham, England

|

Team Turbine - 540 + 720

well, having just sorted my account out on here again (thanks Glen) i figured i should do a build diary of what ive been upto for the past few years, as its been a while since i posted my old 360 build diary up... plus im working a slow nightshift so this will give me something to do...

Since building 360 i built an over complicated interchangeable 6wd magnet pusher/beater robot called 540... on paper it was brilliant, in reality it was far to complex and i was never happy with it, so i decided to sell it on and start on something more combat orientated ... This was 540;

6wd dewalt powered

In high gear it was great, but the dewalts kept blowing up when running the magnets which i really wanted to do... and in low gear it was too slow and boring, so i stripped out the dewalts and build my own speed 900 gearbox to fit in the same spot

These were flawed... i used MOD1 in 2 stages, the smaller gear kept wearing out way to fast or shearing teeth... but it did work well at times;

http://www.youtube.com/watch?v=bpei2vKm8kA

the beater weighed about 1.5kg and span upto 8000rpm in under 2 seconds, and without that on and the magnet in and the front wedge plate placed in, it was un stopable as a pusher, slamed other stuff around like a heavyweight v a feather... but i was never happy with it... below are some pictures;

Naked next to its bro;

armour nearly finnished, had to cut the top and replace with titanium to get it in weight;

front bash plate in place for fighting big horizontals.. all the shell was 4mm hardox 400;

All ready for the UK champs... where it just kept craping out gearbox's, but it looked good lol;

Off she goes to the new owner...who since got rid of the brushless on the beater, put another speed 900 on the drive, and is running the old dewalts in low gear...

720!

Decided this time i wanted to build something to do well that was nice and simple...it had to be easy to maintain with of the shelf parts so i could carry enough spares, capable of quick turn arounds between fights, strong so it could drive head first into the biggest spinners without the need of a front bash plate, and still have a weapon capable of mashing up all the little plastic push bots over here.

Decided the best way to go about it was to make a solid little drum robot that would be tenacious rather then delivering one massive hit like 360 did, and falling apart like 540 did.... so i decided on the most important parts i wanted to use.... I found the banebots site and ordered some motors and gearbox's... i then ordered some botbitz Tz85's... as id seen on this forum how much success all you guys had with them, and no one else here in the UK had ordered them up until that point (think i changed that!)

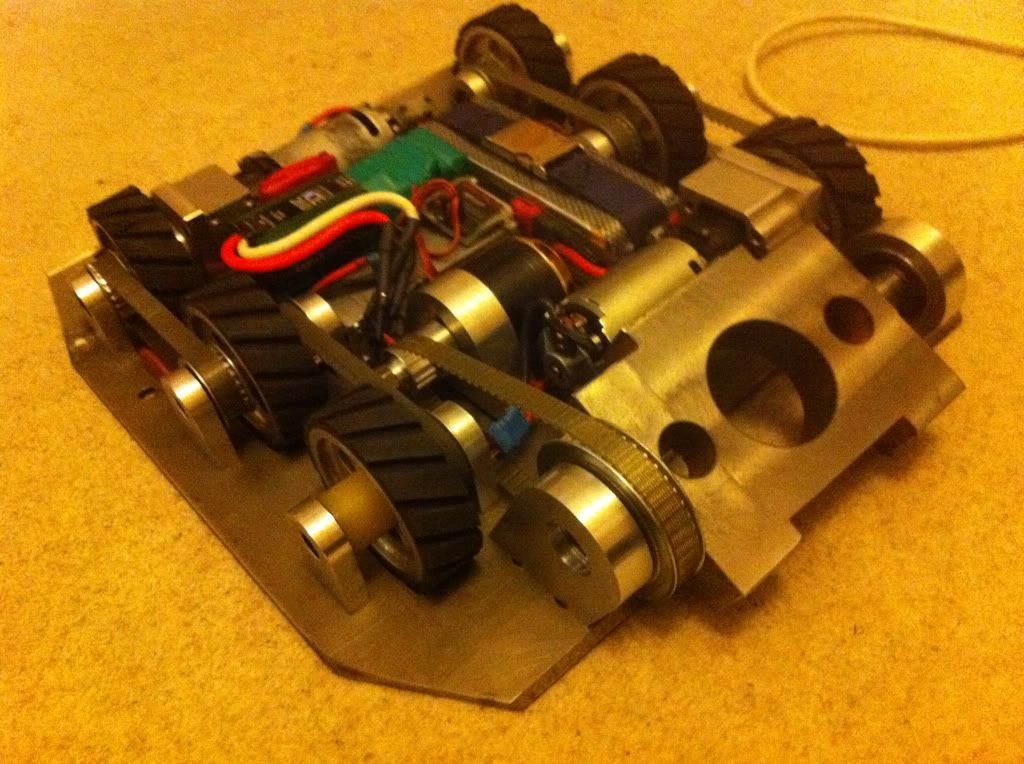

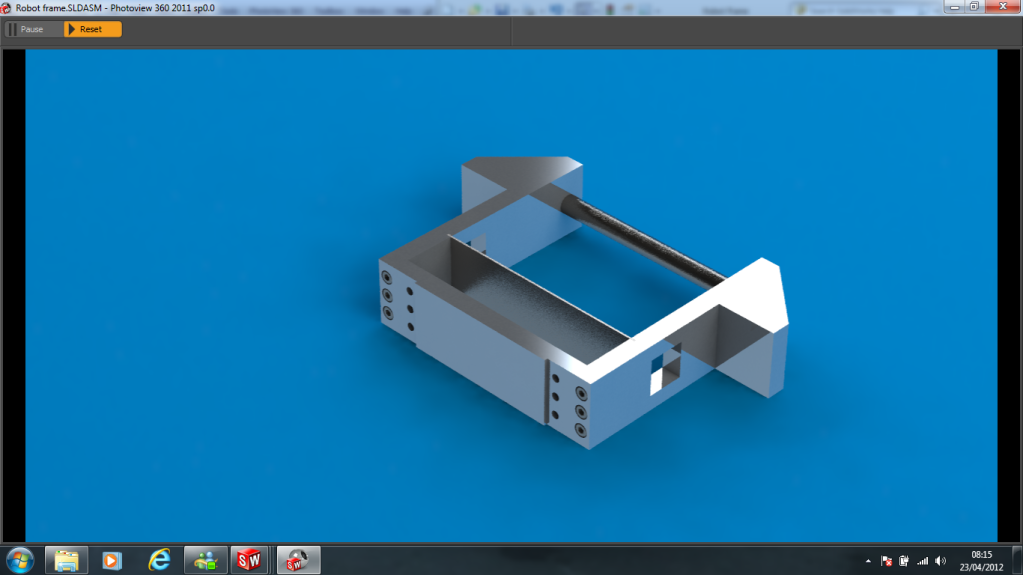

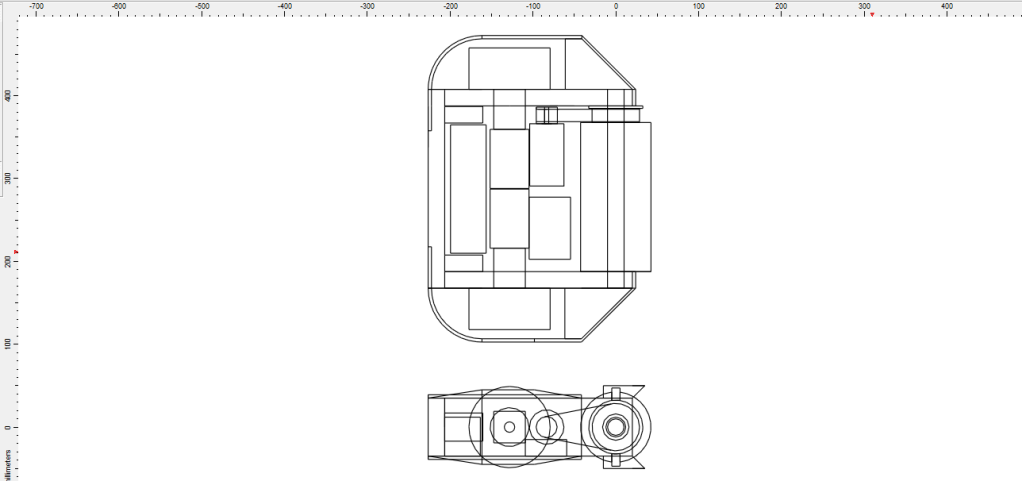

so i got some and did some tests and was real impressed with the brake functions and the size of the botbitz so started to CAD the strongest chassis i could around them;

once i was happy, i made the buisness end from a billet of ali, so it was solid 80mm bar with a 30mm hole in the centre, the shaft is solid 20mm silver steel which is keyd into bulkheads 15mm deep on each and tourqued up with an M10 bolt either side... then either end runs on angular thrust bearings.

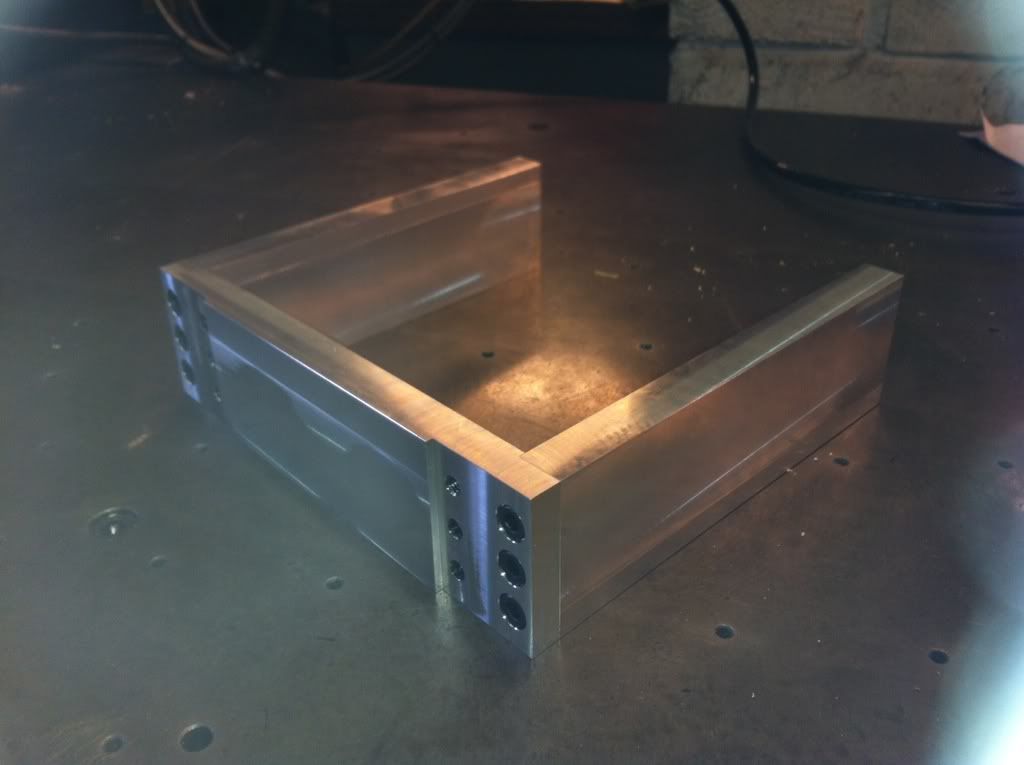

I then broke out the mill with the help of a friend and got to making the chassis, which is all solid 20mm alumec 86 (mega strong aloy)

skimming the billets down the correct sizes;

Yeah its end taped... but there 8mm bolts into 20mm metal.. and the corners arent exposed so its pretty strong;

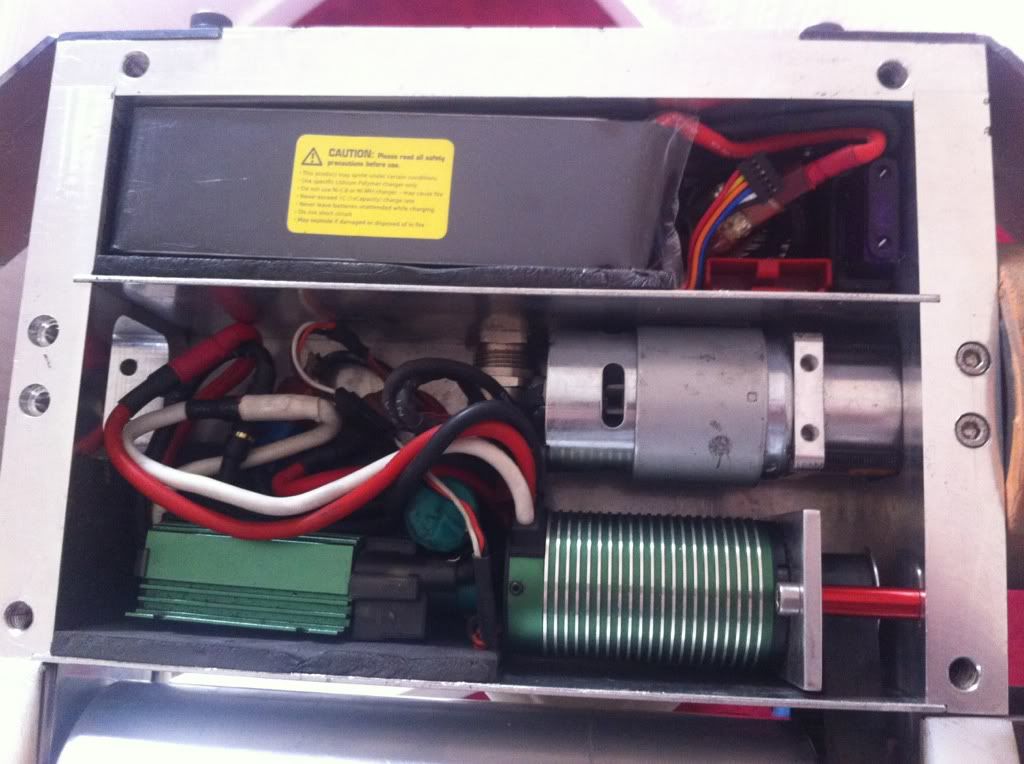

chucked the bits in... all looking good

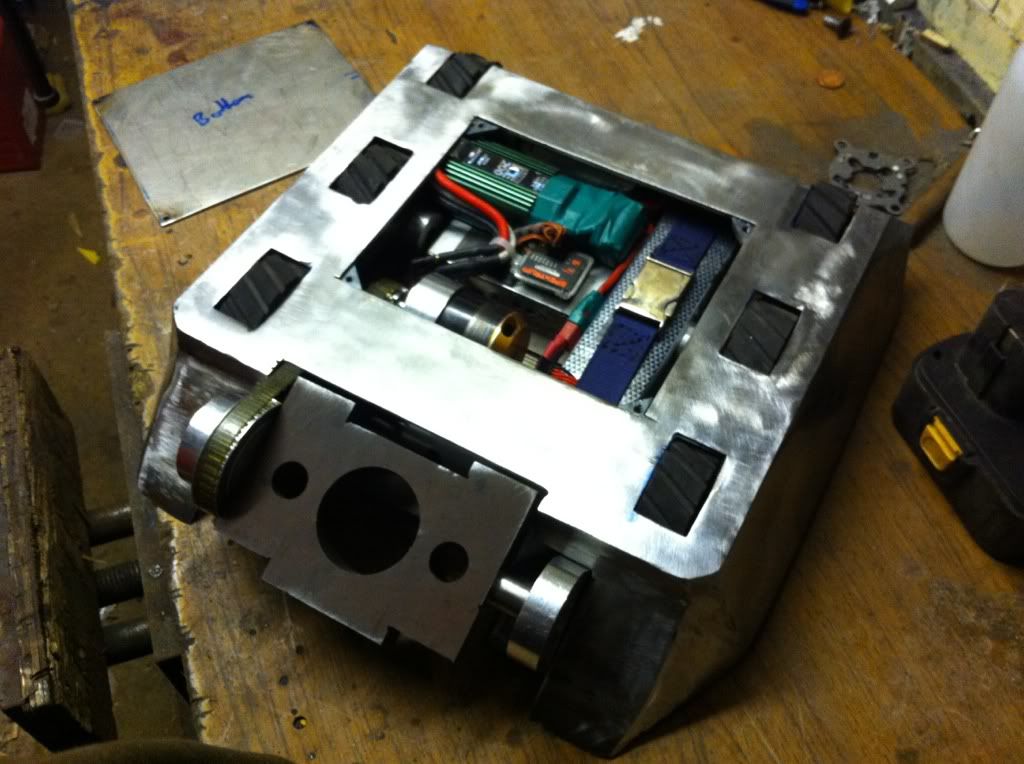

made some armour;

this view shows the motor mounting (now changed) and the wiring,,, the botbitz sit snug under the lipo...

[img][/img]

[img][/img]

view of internals (minus one drive motor) showing wiring, thats a castle creations 2200kv motor running 3:1 on the drum and everything running of one 5000mah thunderpower lipo... the drum weighs 3kg and spins upto 13500rpm in a few seconds... really happy with the results, added an editional capacitor to the brushless esc (ice 200a) and i havnt had en electrical problem so far.

During testing the teeth which were tool steel 10mm wide, 15mm long and key'd in 10mm deep completely shattered and just werent upto the job... so i decided to go as beefy as i could... i made the new teeth from stainless (decided to try a softer metal so it would last long as its not a cutting weapon) and made big T slots, 16mm teeth with a 25mm T at the base... i then pressed those into the drum real snug... i also profiled them so one tooth had one long single tooth in the middle... the oposing tooth had 2 shorter ones at the ends... giving a single tooth effect on impacts.. this improved the drum 10 fold and hasnt broken since, despite me driving into the arena walls fall speed trying to break them;

the teeth are then held in just incase with a retaining ring.. theres no bolts at all hold the teeth themselfs;

then it was finnished!;

At the uk champs this year it came 3RD overall, which im pretty happy with for a first time out putting it the highest ranked spinner in the uk, and i knocked out the current champion on the way to 3rd.

this was my favourite fight - a melee;

http://www.youtube.com/watch?v=JsgFYHUEX4c

and taking out the current champ in the 3rd place playoff;

http://www.youtube.com/watch?v=8leK4GONEio

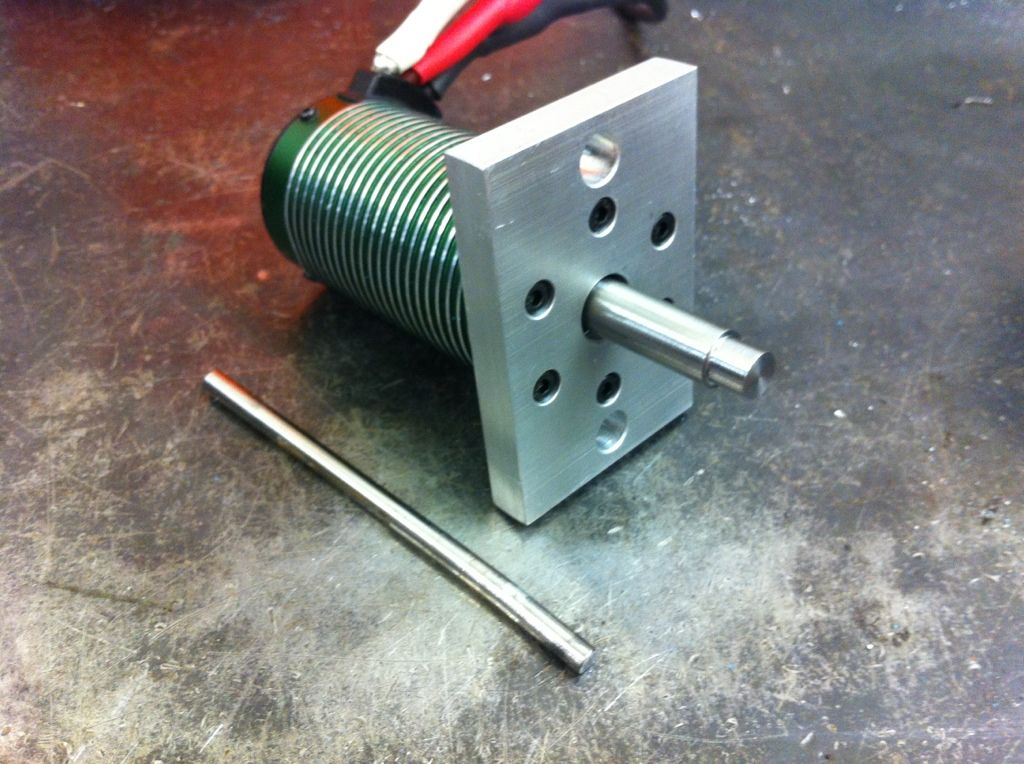

Sam hit me directly on the belt in the last impact, ripping it off... this in turn pulled on the drum motor which bent the shaft (only 5mm) so the next mod im doing is replacing the motor front plate/motor mount for a custom one piece item... so the front of the motor is now the mount... this will also include a 10mm bearing, then the shaft exstends into the oposite bulkhead where its supported with an 8mm bearing... the pulley is also now on the shaft with a proper 3mm keyway, not just a grubscrew for next year... picture of the custom motor front/mount;

original shaft pressed out the centre of the motor and my new custom silver steel one in, and put onto the new front plate with large bearings, i also doubled up the 3 M3 bolts for 6 off, then helicoiled the threads for more strength;

new shaft next to the old bent one;

Mounted to the bulkhead with the supporting bearing in view;

The next modification im working on is a new drum for 2014, its machined from a solid billet of GR5 Titanium with hardox 500 teeth, ive machined the blank teeth and turned the titanium bar down to size... but as you can imagine thats taking AGES to machine... as and when ill get some pictures up of that.

Hopefully my build diary has been of interest to someone and might inspire someone else to get out in the shed building!

|

Wed Aug 21, 2013 6:01 am

Wed Aug 21, 2013 6:01 am |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RoboWars Australia Forum Index

-> Builders Reports

RoboWars Australia Forum Index

-> Builders Reports