|

|

dyrodium

Experienced Roboteer

Joined: 24 Aug 2004

Posts: 6476

Location: Sydney

|

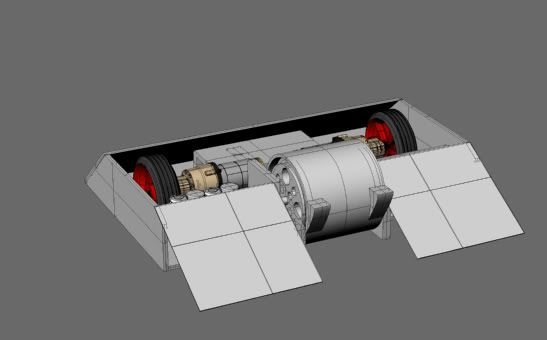

Snack Masheen- Team Dyrodium NSW

Well it's practicaly set in stone now, team dyrodium's next major bot will be a drum bot!

Introducing Ti-Lust

Specs;

Drives: First version will be 12v drills overvolted to 18v, then an eventual upgrade will see 18v DSE drills at 18 or 24v eh eh.

Weapon: Composite drum weapon, made up of four 20mm "slices" of bizalloy lazer cut, then bolted together with really good bolts!  Teeth are part of the drum so no risk of them snapping of. The weapon motor is a low profile but high power, salvaged at PnP Teeth are part of the drum so no risk of them snapping of. The weapon motor is a low profile but high power, salvaged at PnP  at 18v it should have easily enough to spin the drum at a nice speed. I'm also planning to form the bearings into the drum as well, making either the two outside or two inner sections so they accept the bearings. Not sure about going with friction or belt drive yet. at 18v it should have easily enough to spin the drum at a nice speed. I'm also planning to form the bearings into the drum as well, making either the two outside or two inner sections so they accept the bearings. Not sure about going with friction or belt drive yet.

Armour: Well it wouldn't be called Ti-Lust for nothing would it? Rear and side armour is 5.5mm thick, and the front two wedges are 2.5mm. The under front and base as well as titanium side supports are good old aluminium...

Also my problem is my GWS only charges up to 14.4v, so i'll have to have two split packs, but 18v doesn't split evenly, so I may run at 16.8v instead.

_________________

( •_•)

( •_•)>⌐■-■

(⌐■_■)

YEAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAH

Last edited by dyrodium on Mon Jul 03, 2006 9:33 pm; edited 1 time in total

|

Sat May 06, 2006 9:51 pm

Sat May 06, 2006 9:51 pm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RoboWars Australia Forum Index

-> Builders Reports

RoboWars Australia Forum Index

-> Builders Reports